Release Productivity in Your Stockroom Procedures With a High-Quality Stretch Wrapping Machine

Productivity in warehouse operations pivots on the performance of the product packaging procedure. The intro of a top notch stretch covering device can be a game-changer, appealing efficiency, reduced labor costs, and decreased human mistake. With the ability to manage different load dimensions and cover many pallets per hour, these makers use a compelling proposal for any kind of service seeking to enhance its operations. What makes these makers such an essential asset in warehousing? Allow's check out further.

Recognizing the Function of Stretch Wrapping Machines in Storehouse Operations

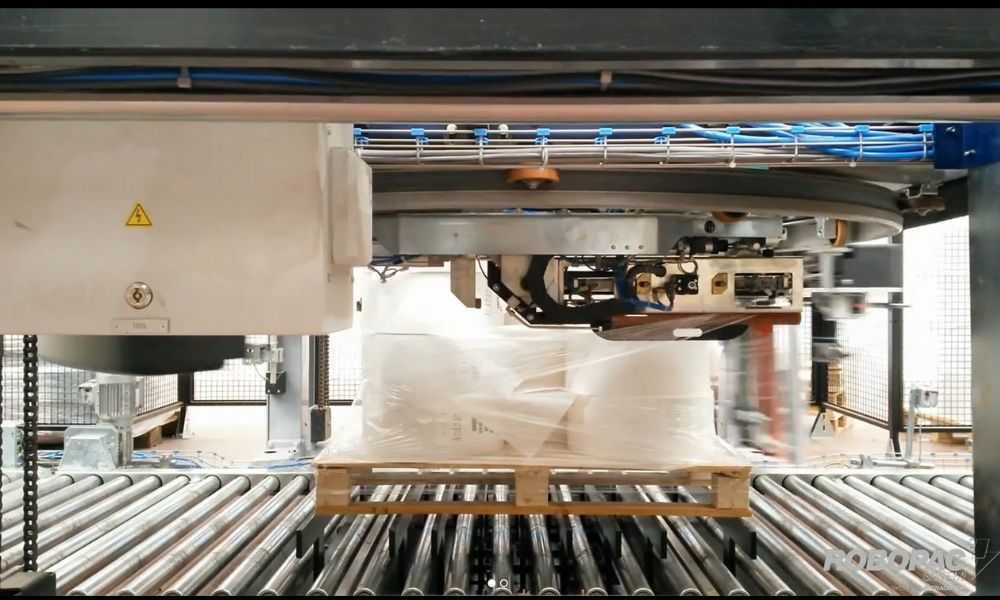

In the huge realm of stockroom operations, the relevance of stretch wrapping makers can not be overstated. They serve a critical function in making certain that items are securely and securely bundled for storage or transportation. These machines apply a very stretchable plastic film around items, firmly covering them with each other in a method that hands-on covering merely can not match.

Stretch covering devices can deal with big volumes of products swiftly, substantially speeding up the packaging procedure. The consistent covering offered by these devices can decrease the risk of tampering or theft throughout transportation.

Trick Features of High-Quality Stretch Covering Machines

While there is a wide array of stretch wrapping equipments offered in the marketplace, top notch models share specific key functions that set them apart. These makers are normally durable, designed to stand up to substantial usage without endangering on performance. They use a high level of automation, allowing for effective and hassle-free covering of items.

Top quality stretch covering equipments additionally include flexible settings, offering versatility to match numerous product packaging requirements. They can take care of different sizes and kinds of tons, making certain a protected wrap each time. These devices are likewise renowned for their rate, with the ability of covering countless pallets per hour, thus considerably improving efficiency.

An additional trick attribute is their reliability and low maintenance requirement. Premium makers are developed to last, minimizing the regularity of failures and the linked downtime. In addition, they run with accuracy, making certain regular cover stress, consequently lowering waste and boosting the discussion of covered products.

The Impact of Stretch Covering Equipments on Stockroom Effectiveness

The performance of a storehouse can be considerably improved with using top notch stretch covering machines - stretch wrapping machine. These devices streamline the packaging procedure, lowering the hands-on labor included and subsequently, the chance for human mistake. This ensures a more reputable and consistent wrapping procedure, resulting in boosted security of items during transport

In addition, stretch wrapping makers can handle a higher quantity of goods in a much shorter amount of time contrasted to manual wrapping. This enhanced productivity can lead to far better use of warehouse area as items can be packaged and relocated faster. The equipments also provide the adaptability to accommodate different dimensions and forms of goods, even more boosting functional efficiency.

Computing the Return on Financial Investment for a Stretch Wrapping Machine

Taking into consideration the considerable advantages of stretch wrapping machines, it's crucial to recognize the monetary implications of spending in such devices. The return on investment (ROI) estimation is a basic yet effective device to examine the profitability of this financial investment. The ROI is determined by contrasting the expense of the machine with the financial savings generated over a details period.

The greater the ROI, the extra successful the financial investment. This number must not be the single factor in the decision-making procedure. Services must likewise think about aspects such as calculated positioning, operational effectiveness, and scalability. To conclude, calculating the ROI offers a clear financial viewpoint to lead the financial investment decision in stretch wrapping machines.

Real-world Case Researches: Success Stories of Carrying Out Stretch Wrapping Machines

Attracting from the monetary effects gone over in the previous section, it is just as enlightening to examine practical applications and success tales of companies that have actually executed stretch covering devices why not find out more in their procedures. One such instance is an international electronics company which reported a 30% decrease in harmed products throughout transit after presenting stretch wrapping makers in their packaging process.

An additional success story entails a leading food and beverage firm. After implementing a stretch covering machine, they experienced a significant renovation in their packaging rate, which subsequently enhanced daily results and overall efficiency.

Last but not least, a popular furnishings manufacturer was able to reduce down their product packaging material expenses by an astonishing 40% after switching to stretch wrapping equipments; they concurrently reduced their carbon footprint, making their procedures extra sustainable. These real-world study show the impressive returns and effectiveness gains that extend covering equipments can bring to storehouse procedures.

Final thought

To conclude, spending in a premium stretch wrapping machine can considerably improve stockroom operations. With its capability to lower manual work, reduce errors, and enhance area use, it significantly improves performance and productivity. The ROI, paired with success tales from real-world executions, better emphasizes the essential duty of stretch covering more equipments in achieving operational efficiency and company success.

The introduction of a premium stretch wrapping machine can be a game-changer, promising efficiency, lowered labor prices, and lessened human error.In the large realm of storehouse operations, the importance of stretch wrapping equipments can not be overemphasized.The effectiveness of a storage facility can be considerably improved with the use of top quality stretch wrapping machines.Additionally, stretch wrapping machines can take care of a higher quantity of items in a much shorter amount of time compared to hand-operated covering.In final thought, spending in a top quality stretch covering maker can significantly boost storehouse operations.

Comments on “How a stretch wrapping machine reduces packaging waste”